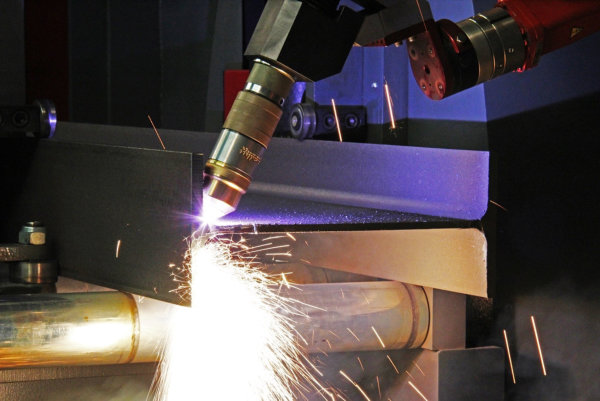

Beam Coping Machine Winding

Voortman offers regularly scheduled training courses for all Voortman Ocean equipment in their Bradley Illinois facility. These courses are available for both new operators and retraining existing operators. Participants who have completed this course return to the shop motivated, educated and eager to improve productivity. Please contact us for more information and pricing.

Voortman developed Raptor 3DCAD/CAM Software, which takes CNC innovation to the next level by allowing users to program more quickly and accurately. The 3D platform allows you to inspect, modify, and export part information. This, combined with Voortman CNC technology, means maximum fabricator capacity.